Temperature Measurement Products

FlareSpection

Infrared Camera System for Continuous Pilot Flame and Flare Stack Monitoring

FlareSpection provides real-time, pilot flame, flare monitoring, and flaring status necessary for safety, environmental protection, and governmental compliance

- Continuous, remote, and automatic monitoring of pilot flames and flared gases

- High-resolution (640 x 480 pixels) thermal imaging camera combined with high magnification optics, provides unmatched spatial resolution and superior image quality

- Advanced software to enable automated and seamless integration with a plant’s distributed control system (DCS)

- Explosion-proof, stainless-steel enclosure designed for hazardous areas

- Alternative or secondary backup system to conventional thermocouples can be installed and repaired without shutting down the plant

- Overview

- Technical Specs

- Documents

- Accessories

- Service & Support

- Distributors

Overview

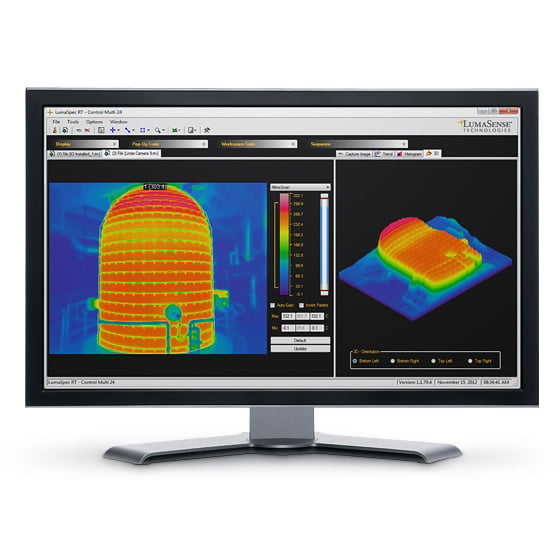

The FlareSpection™ system provides extremely clear and reliable flare image and pilot flame monitoring of multiple flare tips. FlareSpection optimizes plant operations, improves safety, and ensures regulatory compliance. It enables you to remotely and automatically confirm flare operation and detect differences in flare stack heat signatures.

Designed with optimized spectral ranges, a high-resolution thermal imaging camera, and high magnification optics, this system continuously monitors through moisture, heavy rain, and fog from hundreds of meters away. Its certified explosion-proof housing enables the system to be located in hazardous areas. You can also confirm pilot flame and flare presence, detect plant performance deviations, and set alarms using the system’s advanced software.

Benefits

- Detect multiple pilot flames and flares simultaneously and continuously, ensuring safe and compliant flare monitoring

- Reliably monitor pilot flames and flares with minimal false alarms, increasing plant uptime

- Accurately monitor from hundreds of meters away, giving great flexibility to choose the remote flare monitoring system's location

- Install in hazardous plant areas thanks to explosion-proof housing (certified)

- Avoid costly regulatory fines and unscheduled downtime

- Continue plant operation if thermocouples fail, long-term remote monitoring system can serve as a backup to conventional thermocouple monitoring

- Be immune to factors such as flame movement, varying luminosity, and adverse climatic conditions

- Easily connect to the plant's DCS via protocols, such as Modbus and OPC, as well as connections to pilot ignitors via traditional I/O relay modules

Features

- High-resolution thermal imaging camera combined with high magnification optics provides high-resolution image of pilot flames and flares

- ATEX, IECEx, US, and Canada certified explosion-proof housing

- Stainless-steel enclosure with an integrated sighting tube to prevent dust and dirt on the window

- Easy installation and maintenance from remote mounted location

- Rugged, adjustable mount and base provides stable alignment of the system to pilots and flares (no periodic adjustments required)

- Advanced software to log performance, record video, and set up alerts for measurements that may fall outside of the plant’s preset limits

- Image, event, and alarm logs stored for audits

-

Performance

Image Update Rate

9 Hz

Pixel Pitch

17 µm

Detector

640 x 480 uncooled microbolometer

-

Optical Specifications

Lens Focal Length

200 mm

Field of View (FOV)

3° horizontal x 2.3° vertical

Digital Zoom

1 to 8x using LumaSpec RT software

-

Interface

Interfaces

OPC, Modbus Serial, Modbus Ethernet, Analog Contact Outputs, Relays

Power Input

24 VDC

-

Environmental Specifications

Hazardous Classification and Environmental Protection

ATEX II 2 G Ex db IIB T4

IECEx Ex db IIB T4

US/Canada: Class 1 Div 1, Group C and D T4; Class 1 Div 2 Group A, B, C and D T4Operating Temperature

-30 to 50°C (32 to 122°F)

Storage Temperature

-20 to 70°C (-4 to 158°F)

Weight

~ 38 kg (~84 lbs)

Housing

316L stainless steel suitable for hazardous areas

-

Electrical

Power Input

12 and 24 VDC

-

Typical Applications

- Flare monitoring

Specifications are subject to change without notice. Not all options and accessories are available for all models and configurations. Dimensions listed generally refer to standard configurations and module bodies only. Please confirm technical specifications and customizations with a sales representative. Advanced Energy is not responsible for errors or omissions.

Data Sheets

Brochures

Manuals

Accessories

Documents & Support

View All FlareSpection AccessoriesGlobal Support & Services

Maximize fab productivity and capital equipment ROI with world-class support through each product lifecycle stage — from startup to long-term operation. Our service offerings are based on more than three decades of precision power and applications expertise.

Applications Support & Consulting

Accelerate tool installations and process development programs, or address specific applications concerns with Advanced Energy's dedicated applications consultants and engineering staff. Benefit from on-site reviews, analyses, and consultations.

Warranties

Decrease variability in maintenance costs and provide additional cost protection. Advanced Energy offers whole-box extended warranties.

Product Support

Call

U.S.: +1 800 446 9167

Asia: +86 29 8874 1895

China: 400 8899 130

EMEA: +44 800 032 1546

U.K.: 08000 321 546

Email

Thin Film Support

Thermal Product Support

Other Technical Support

Find an AE Representative or Distributor

To find distributors and representatives who sell AE products in your area, select your location and vendor type (optional).